How to Guarantee Quality with Welding Inspection Gilbert Arizona: Best Practices

How to Guarantee Quality with Welding Inspection Gilbert Arizona: Best Practices

Blog Article

A Comprehensive Guide to Welding Inspection: Comprehending Standards, Techniques, and Finest Practices for Top Quality Assurance

Welding examination plays an essential duty in making sure the structural stability and safety of bonded components, necessitating a detailed understanding of sector requirements such as those established by AWS and ASME. As we discover these vital aspects, it ends up being obvious that the ramifications of welding evaluation prolong far beyond compliance, welcoming a more detailed exam of just how these processes form market requirements and techniques.

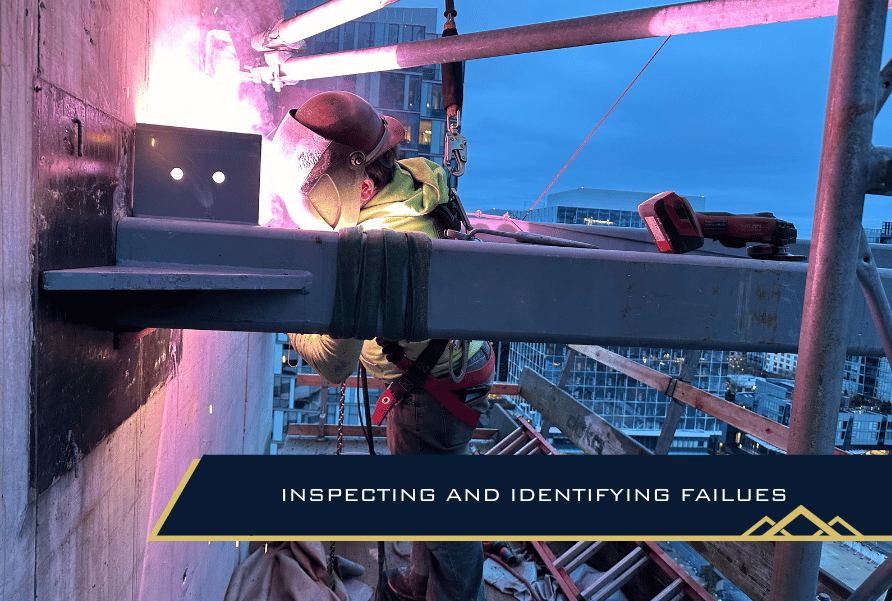

Value of Welding Assessment

Welding assessment plays an essential role in making sure the stability and safety of welded structures. It is a crucial process that validates that welds adjust to predefined specs, which is vital in various sectors, consisting of building and construction, automotive, and aerospace. By conducting detailed examinations, prospective issues such as fractures, insufficient combination, and porosity can be recognized early, avoiding devastating failures that could result in mishaps or pricey repair services.

The value of welding evaluation prolongs past simple conformity with regulations; it likewise fosters depend on with stakeholders. Customers and governing bodies expect guarantee that the frameworks they rely upon are constructed to endure operational stress and anxieties. In addition, efficient welding evaluation methods add to long-lasting longevity and efficiency of the structures, eventually bring about minimized upkeep expenses.

Additionally, welding assessment advertises a culture of quality within companies, urging adherence to best methods and continual improvement. By incorporating evaluation procedures right into the welding workflow, companies can enhance their online reputation and develop themselves as leaders in top quality assurance. Finally, the value of welding evaluation depends on its capability to secure lives, make sure structural integrity, and copyright market standards, making it an indispensable facet of welding procedures.

Key Market Standards

Ensuring compliance with essential market criteria is important for keeping the quality and safety and security of bonded frameworks. Different organizations develop these requirements to promote ideal techniques in welding and evaluation. Amongst one of the most recognized are the American Welding Society (AWS) and the American Culture of Mechanical Engineers (ASME), which offer in-depth standards and specifications for welding processes and inspection requirements.

AWS standards, such as AWS D1.1 for structural welding, synopsis demands for products, design, and screening to make certain the honesty of welds. ASME codes, consisting of ASME Section IX, regulate the credentials of welders and welding treatments, ensuring regular quality in industrial applications. Globally, the ISO 3834 basic highlights quality demands for blend welding, offering a structure for companies to demonstrate compliance with global ideal techniques.

Conformity with these requirements not just improves the reliability of welded frameworks but additionally minimizes risks linked with structural failures. Adherence to sector requirements is frequently a prerequisite for regulative approvals and can significantly affect job specifications. Inevitably, understanding and implementing these key standards are important for reliable welding inspection and quality control.

Evaluation Techniques Review

Effective welding assessment depends on a variety of methods designed to analyze the high quality and integrity of welds. These strategies can be broadly classified right into damaging and non-destructive screening (NDT) methods. Non-destructive screening strategies, which are widely preferred in the market, enable the analysis of welds without jeopardizing the stability of the product.

Among the most frequently utilized NDT strategies are visual assessment, ultrasonic screening, radiographic testing, and magnetic fragment testing. Aesthetic evaluation is commonly the first step in the analysis procedure, allowing assessors to identify surface area blemishes and examine weld grain profiles.

Each technique has its own benefits and limitations, making it crucial for assessors to pick the most ideal method based upon the details needs of the project, the materials entailed, and find here the criticality of the welds being examined. This careful choice guarantees detailed assessments and maintains security and high quality criteria in welding operations.

Usual Issues and Their Ramifications

A complete understanding of typical issues in welds is essential for preserving architectural integrity and safety and security in bonded buildings. Welding defects can considerably compromise the mechanical residential properties of the joint, causing failures that could jeopardize both workers and tools.

Typical problems include porosity, which shows up as tiny gas pockets trapped in the weld steel, damaging the overall framework. Cracking is another widespread problem, usually resulting from fast cooling or improper joint layout, bring about stress focus that can result in disastrous failures. Incomplete blend occurs when the weld metal stops working to correctly bond with the base material, producing weak factors that might result in splitting up under load.

Various other notable flaws consist of damaging, where the weld grain erodes the base metal, and slag incorporations, which can prevent the weld's strength. Each of these issues has details ramifications; for example, porosity can decrease ductility, while fracturing straight influences tensile stamina. Recognizing and comprehending these flaws during assessment is vital for guaranteeing and carrying out corrective measures compliance with industry standards, eventually protecting the structural honesty of bonded assemblies.

Ideal Practices for High Quality Guarantee

Applying ideal methods for quality control in welding processes is important for read the full info here attaining optimum outcomes and lessening defects. One essential practice is the facility of clear welding procedures that comply with industry requirements and specs. These procedures must consist of in-depth guidelines regarding material choice, joint preparation, and welding strategies to make sure consistency and quality.

Normal training and accreditation of welding workers are also crucial. Skilled welders that understand the value of quality control are more most likely to generate sound welds. In addition, executing a durable inspection program, consisting of both aesthetic and non-destructive testing (NDT), can help identify flaws early in the procedure, permitting timely corrective activities.

Paperwork plays a crucial duty in quality control. Preserving precise records of welding fixings, parameters, and inspections makes sure traceability and responsibility. Using sophisticated technologies such as automated welding machines can boost precision and lower the capacity for human error.

Finally, fostering a society of top quality within the organization motivates employees to focus on quality in their job. By adhering to these ideal methods, organizations can boost the stability of their welding procedures, ultimately leading to improved product quality and lowered costs linked with rework and fixings.

Verdict

In conclusion, welding inspection plays an important duty in ensuring the honesty and safety and security of welded frameworks. By executing ideal practices, companies can enhance dependability, decrease upkeep costs, and grow trust fund among customers, eventually contributing to effective welding operations.

In addition, welding assessment promotes a society of top quality within organizations, urging adherence to finest techniques and continual enhancement. In verdict, the importance of welding assessment lies in its capacity to protect lives, ensure structural dependability, and copyright industry criteria, making it an essential element of welding procedures.

Amongst the most identified are the American Welding Culture (AWS) and the American Culture of Mechanical Designers (ASME), which give comprehensive guidelines and specifications for welding More Help processes and evaluation criteria.

Eventually, understanding and applying these crucial standards are vital for effective welding inspection and top quality assurance.

Reliable welding evaluation depends on a variety of techniques created to examine the high quality and honesty of welds. - Welding Inspection Gilbert Arizona

Report this page